Achieving Supply Chain Transparency with Digital Standards

Supply chain transparency is no longer a competitive advantage, it’s a baseline expectation. As consumers, regulators, and partners demand greater visibility into sourcing, production, and ethical practices, businesses must adopt digital standards that unify data, enable traceability, and foster trust.

This blog explores the key dimensions of transparent supply chains, the role of digital standards, and steps businesses can take to build ethical, future-ready supply chains.

Table of Contents

What is Supply Chain Transparency?

Supply chain transparency refers to a company's ability to be open and accountable about the materials, products, and practices throughout its supply chain. This involves understanding and disclosing information about everything from raw material sourcing and manufacturing processes to the environmental and social impacts at each stage.

It's a key part of modern corporate responsibility and can help build trust with consumers, investors, and regulators.

Its scope covers labor conditions, supplier practices, environmental impact, and compliance with laws such as the California Transparency in Supply Chains Act. Tools like blockchain, Internet of Things (IoT), and AI help companies trace and share this data in real time.

With the rising complexity of global supply chains, transparency has become essential for responsible sourcing, ESG (Environmental, Social, Governance) reporting, and protecting brand reputation.

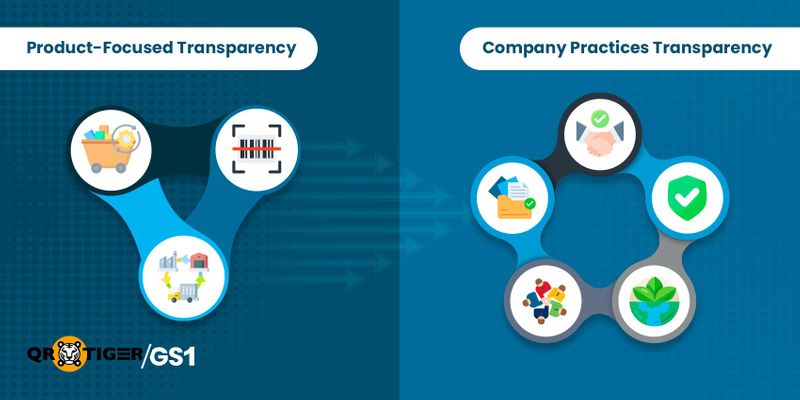

Two Dimensions of Supply Chain Transparency

Transparent supply chain systems operate on two key levels: product-focused and organizational. Both are essential for building trust, ensuring compliance, and driving ethical decisions across the value chain.

Product-Focused Transparency

Product-focused transparency involves tracking and sharing detailed information about a product’s journey from raw material origin to the end consumer. It aims to make every step in the supply chain as visible, verifiable, and compliant as possible with ethical, environmental, and regulatory standards.

Let’s get a brief on its essential components:

Traceability and visibility: Companies rely on barcodes and GS1 standards as the foundation for tracking products from raw materials through production and delivery. In addition, tools like RFID (radio frequency identification), IoT sensors, and blockchain are increasingly used to add deeper visibility, monitor conditions, and secure data across the supply chain.

Tracking Data and Analytics: Businesses collect data in real time from different stages of the supply chain. This allows them to spot disruptions, delays, or quality issues more quickly. Analytics tools help interpret the data, highlight risks, and support better planning.

Data collection and sharing: Data is collected from various touchpoints such as factories, warehouses, transport vehicles, and retail shelves. It is then shared with stakeholders (regulators, partners, consumers) to build trust and accountability in the value chain.

Blockchain ensures data integrity and avoids tampering, ensuring the reliability of the shared information.

Supply chain mapping: The process of identifying and documenting where a company’s materials and components come from. It usually starts with Tier 1 suppliers, the direct vendors a company buys from. For example, if a clothing brand buys fabric from a textile mill, that mill is Tier 1.

However, Tier 1 suppliers often depend on their own providers. These are Tier 2 suppliers, such as the cotton processors who supply the textile mill. Go even further back, and you reach Tier 3 suppliers, like the farms growing the cotton itself.

The deeper a company maps, the more it can uncover hidden risks.

Regulatory product compliance: Ensuring a product meets the safety, labeling, and quality standards required by law in the markets where it is sold. This goes beyond supply chain practices, it focuses on whether the product itself complies with regulations covering health, safety, and consumer protection.

Examples include:

- FDA UDI Rule (United States): Medical devices must carry a Unique Device Identifier (UDI) to ensure traceability, patient safety, and recall readiness.

- EU Food Information to Consumers (FIC) Regulation: Requires specific nutrition, allergen, and origin labeling to provide accurate information to consumers.

- EU REACH Regulation: Restricts the use of hazardous chemicals in products to protect human health and the environment.

- EU CE Marking: Certain products (electronics, toys, machinery) must meet EU safety, health, and environmental standards before being marketed.

Consumer-facing information: Labels showing expiry dates, certifications (for example, Organic, Fair Trade), and sustainability scores help consumers make informed decisions. Dynamic labels and QR codes can link to product histories to enhance transparency and consumer engagement.

Company Practices Transparency

This dimension highlights how companies manage and reveal their supply chain practices, not just product-level data, but the standards, values, and systems that drive sustainable and ethical supply chains.

Supplier code of conduct: A Supplier Code of Conduct defines standards for ethical labor practices, environmental responsibility, and business integrity. Commonly, it includes:

- Prohibitions on forced labor, child labor, and discrimination

- Requirements for safe working conditions, fair wages, and freedom of association

- Audit mechanisms to verify compliance and drive continuous improvement. For instance, Greencore’s code focuses on sourcing with integrity and defines ethical and environmental standards.

Environmental and social impact assessments: These assessments estimate how supplier operations affect people and the planet. It focuses on:

- Carbon footprint: Measures emissions across production and logistics.

- Labor conditions: Reviews worker safety, rights, and well-being.

- Community impact: Understanding how operations affect local communities. Companies like RCL Group support supplier responsibility through environmental compliance and community engagement standards.

Strengthening supplier relationships: Transparency focuses on collaboration with suppliers in the following ways:

- Foster skill development and ethical improvements

- Encourage transparent communication and shared goals

- Promote long-term partnerships based on trust and shared responsibility to improve sustainability performance across an organization’s value chain.

Broader risk management: Organizational transparency helps identify and tackle risks, such as:

- Reputational damage from unethical business conduct

- Legal non-compliance with environmental or labor laws

- Unexpected operational disruptions due to hidden vulnerabilities.

- Mapping supplier networks and enforcing standards helps companies to manage risks and build responsible, resilient supply chains.

Barriers to Supply Chain Transparency

Building supply chain transparency is complex. Companies must overcome business, technical, and regulatory barriers that make collecting and sharing accurate information difficult.

Business and Competitive Barriers

- Protecting trade secrets: A company’s supplier list, locations, and pricing are often seen as its “secret sauce.” Sharing this could let competitors copy their approach and reduce market share.

- Supplier reluctance: Many suppliers, especially smaller ones, don’t want to reveal details. They may worry about exposing other clients or production methods, which can cause secrecy and mistrust.

- Cost and resources: Full transparency takes money and effort. Companies need new systems, training, and processes to manage data from hundreds (or thousands) of suppliers. For smaller businesses, this can be a heavy burden.

Technical and Data Barriers

- Fragmented systems: Supply chains involve many companies, each using different tools for inventory, logistics, and production. These don’t connect well, making it hard to see the full product journey.

- No common standard: One supplier might use spreadsheets, another cloud software. Without consistency, combining the data becomes messy and slow.

- Data security risks: Sharing more information raises the chance of breaches. Strong cybersecurity is needed to protect sensitive supplier and product details.

Regulatory and Logistical Barriers

- Complex supply tiers: A single product can involve many hidden layers of suppliers. For example, a T-shirt brand (Tier 1) uses fabric from a mill (Tier 2), which buys cotton from a farm (Tier 3). Tracing all the way back is complex and requires cooperation at every level.

- Different regulations: Countries have different laws on labor, environment, and data privacy. Managing compliance across borders adds another layer of difficulty.

- Trust issues: Transparency depends on trust. Many supply chains are built on closed-book practices, and shifting to open, shared data is a slow cultural change.

Where GS1 QR Codes fit in

GS1 QR codes provide a standardized way to share product data in a format that is consistent and accessible across the supply chain.

By linking to ingredients, expiry dates, certifications, or sourcing details, they help businesses and consumers access trusted data in one scan.

Their role is to enable transparency, but the level of visibility depends on the quality and depth of data companies choose to share.

What are GS1 Digital Link QR codes?

GS1 QR (Quick Response) codes are two-dimensional barcodes that store much more data than traditional 1D barcodes. They encode details like expiry dates, batch numbers, certifications, traceability data, and web links. They are scannable by smartphones and point of sale (POS) systems, and act as digital gateways to detailed product information.

These codes follow global standards for product identification, using identifiers like GTIN (Global Trade Item Number). This ensures:

- Interoperability across supply chains, retailers, and regions

- Reliable structure for encoding consistent data

- Compatibility with existing systems and future regulations.

- Simplifies data sharing across industries and helps build consumer trust.

Product integration with GS1 QR codes

The features that let these QR codes support product-level transparency goals are:

- Traceability: Link to origin, batch, and logistics data.

- Real-time updates: Dynamic QR codes show current status (for example, product recalls)

- Consumer-facing info: Show certifications, usage instructions, and sustainability scores.

Extending transparency beyond the product

GS1 QR codes are built for product-level data, but they can also connect to documents such as:

- Sustainability reports

- Supplier codes of conduct

With GS1 Digital Link QR codes, brands can showcase ESG efforts and ethical sourcing directly through the code, though this depends on how much data companies choose to share.

Benefits for stakeholders

The codes benefit stakeholders in the following ways:

- Retailers: Improve inventory accuracy and recall readiness

- Regulators: Access compliance data instantly

- Brands: Build trust, reduce risk, and meet global standards

- Consumers: Access to more information before purchase

Companies with skilled teams and technical resources can choose to create GS1-compliant 2D barcodes by following the official GS1 implementation guidelines. If they lack required technical resources or want a faster deployment, they can partner with a trusted third-party provider like QR Tiger’s GS1 QR code generator.

Drives regulatory initiatives

The EU Digital Product Passport (DPP) requires companies to digitally share detailed product data, such as materials, origin, carbon footprint, and recyclability.

Sunrise 2027 is GS1’s global push to support the transition from traditional 1D barcodes to 2D codes like GS1 QR and DataMatrix by the year 2027. These next-generation barcodes can carry far more information, making them ideal for effective tracking and consumer engagement.

Steps to make supply chains transparent

Achieving transparency in the supply chain involves working on technology setup, collaboration, and defining standards. Here are steps businesses can follow:

Assess risks: Begin identifying vulnerabilities, such as counterfeit goods, unethical labor practices, or environmental violations. Assessing risk helps prioritize areas that need visibility and control.

Map supply chain: Document all manufacturers, suppliers, and logistics partners, starting with Tier 1. Mapping provides visibility into who is involved and highlights potential hidden risks. It sets the foundation for product traceability in the supply chain.

Define standards: Establish clear codes of conduct, data-sharing protocols, and sustainability benchmarks. Adopting global frameworks like GS1 standards helps maintain consistency and meet evolving regulatory requirements.

Centralize data: Integrate supply chain data into a unified platform for timely access and analysis. Centralized data improves recall readiness, decision-making, and stakeholder communication.

Engage partners: Work with logistics providers, suppliers, and tech partners to align on data standards, ethical sourcing, and continuous improvement.

Monitor and refine: Use feedback and analytics to track performance, detect gaps, and refine processes. Transparency is not a one-time solution; it is a continuous practice of trust and accountability.

The Future of Transparent Supply Chains

Supply chain transparency isn’t a one-time initiative; it’s a capability that must be built into daily operations. By adopting digital standards like GS1 identifiers and QR codes, businesses can unify product data, simplify compliance, and share meaningful information with consumers and partners.

Its goal is to ensure that accurate, standardized information about products, processes, and movements is accessible across all stakeholders, enabling accountability, safety, and trust. It's about enabling interoperable systems that allow verified data to flow securely and consistently across the entire supply chain.

FAQs

What’s the key difference between transparency and visibility?

Visibility means a company can see what’s happening in its supply chain. This could include tracking shipments, checking supplier performance, or knowing where inventory is at a given time. Visibility is mainly for the company’s own use.

Transparency means sharing that information with others, like customers, business partners, or regulators. It’s about showing the data and explaining choices, especially around ethics, the environment, or social responsibility.

In short, visibility is what a company sees; transparency is what it shares.

Why is transparency crucial in supply chain management?

Transparency is important because it builds trust, improves accountability, and lowers risks. Companies can meet consumer expectations and follow ethical and sustainable practices by sharing details about sourcing, labor conditions, and environmental impact.

It also ensures that problems, like delivery delays or unfair labor practices, are not hidden and are addressed responsibly. A transparent supply chain gives consumers confidence in their choices and helps protect a company’s reputation.

How do GS1 standards help ensure transparency in supply chains?

GS1 standards create transparency by providing unique identification codes (like barcodes and RFID tags) for products, locations, and shipments. This enables companies to track items from origin to consumer, share standardized data across the supply chain, and quickly trace products during recalls or quality issues.

The common data language allows all supply chain partners to access consistent, accurate information about product movement, authenticity, and handling conditions.