The SSCC and the Evolution of Logistics Data Carriers

Traceability is a key part of distribution, often relying on the barcodes you see on boxes, pallets, or entire containers. One of the most important of these is the shipping code. It's a powerful tool for identifying shipments and ensuring smooth movement through warehouses, logistics hubs, and transport networks.

In the following sections, we'll examine how the code works, differs from other identifiers like GTIN, and the latest logistics labeling standard that brings it to life. Lastly, we'll explore how this standard seamlessly transitions between traditional and modern barcodes.

Table of Contents

What is an SSCC?

The Serial Shipping Container Code (SSCC) is a unique 18-digit identifier that tracks shipments. Think of it as a digital fingerprint for boxes, pallets, or containers, ensuring every unit is distinguishable.

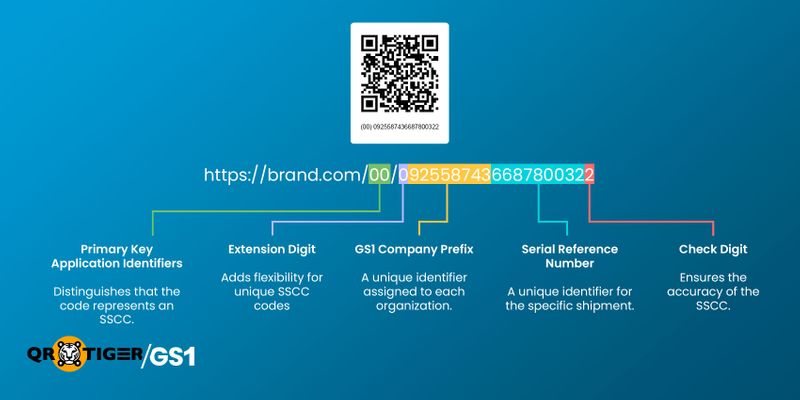

The following components make up the shipment code:

1. Extension digit (1 digit)

The extension digit is the first number in the code. It gives companies more options to create unique codes. The extension digit doesn't have a set meaning and can be used however the company decides, such as to separate different shipments or categories.

The extension digit allows companies to utilize the shipping code for various internal tracking and operational needs beyond basic shipment identification.

2. GS1 company prefix (7-10 digits)

The GS1 Company Prefix is a unique number given to a company by GS1. It works like an ID, linking the codes to the company that made them.

Big companies get shorter prefixes to create more codes, while smaller companies get longer prefixes because they need fewer codes.

3. Serial reference (6-9 digits)

This part is a unique identifier that the company chooses to identify each shipment. It's often called a Shipping Reference Number or Waybill Number.

The length and format of this number can vary greatly depending on the company's system. For example, a company might use a 10-digit alphanumeric or 15-digit numerical code.

Each shipment, whether a single box or a full truckload, receives its unique reference number.

4. Check digit (1 digit)

Check digits are like safety checks for codes. They help catch mistakes, like typing errors or scanning problems.

The check digit is usually the last number in the code and is worked out using a math formula based on the other numbers. The formula can be different depending on the type of code, like an ISBN or UPC.

When the code is scanned or typed, the system rechecks the math. If the check digit doesn't match, there might be a mistake in the code.

Difference to GTIN

Unlike the Serial Shipment Container Code, the GTIN uniquely identifies individual trade items, such as a box of cereal or a bottle of shampoo. It helps businesses manage retail sales, inventory, and B2B transactions.

Use case for each code

- Manufacturers, stockers, and retailers scan GTINs when individual items are made, stored, or sold at the point of sale. Businesses use this code to add a single product to inventory, place it on a retail shelf, or scan it at checkout.

- Shipment codes are used at the logistics level. Workers scan them when assembling shipments, tracking them through warehouses, loading them onto trucks, or receiving them at a distribution center. For instance, an SSCC 18 identifies a pallet moving from a factory to a retailer's storage facility.

GTINs handle product-level identification, ensuring accountability for each item at its most granular level. On the other hand, shipment codes streamline the movement and tracking of grouped items through distribution channels.

Together, they enable complete traceability from production to delivery, connecting product-level and shipment-level data seamlessly.

The GS1-128

Since the late 1980s, the SSCC has been encoded in a GS1-128 barcode (originally called EAN-128), which became the global standard for labeling transport units.

By design, the barcode combines the shipping code with additional information such as batch number, production date, or weight, making it reliable for moving goods through structured supply chains.

Still, the GS1-128 has notable limitations within logistics:

Identifier only

The barcode itself does not contain delivery instructions or tracking updates. It simply carries the shipping code. The identifier must be looked up in the relevant IT system to obtain delivery status or routing details.

Size and space requirements

GS1-128 barcodes are long and require a significant amount of label space. Printing and scanning can become problematic on smaller packages or irregular surfaces.

Scanning conditions

The barcode depends on linear laser scanning. Labels must be correctly positioned, free from damage, and accessible. Scanning performance decreases if a pallet is shrink-wrapped, stacked tightly, or the label is obscured.

Data capacity and efficiency

While GS1-128 can carry multiple Application Identifiers, the data string quickly becomes long. This increases print density, which raises the chance of scanning errors in fast-moving operations.

The Scan4Transport standard

While the GS1-128 barcode has proven itself as a tried and tested tool for decades, logistics is evolving, and so should labeling. The next step is the GS1 Scan4Transport (S4T) standard.

S4T builds on the foundation of GS1-128 but takes it further. Instead of only carrying identification numbers, it uses the GS1 Digital Link. This web URI-based syntax encodes key data, such as the shipping code and more, directly into a QR code.

This approach shifts labeling from being just a scannable ID to becoming a gateway to richer information. With one scan, logistics partners can access shipment details, routing instructions, compliance data, and even digital documents.

Parts of an S4T label

A key part of its design is ensuring compatibility during the industry's transition to 2D barcodes. Therefore, the S4T standard explicitly requires that a label contain both barcodes:

A GS1 Digital Link URI in a 2D barcode (like a QR code or Data matrix): This provides the primary, data-rich scan for modern systems, capable of holding the primary identifiers and other data, plus linking to online information.

A GS1-128 barcode: This serves as a critical backup for distribution centers and logistics partners whose scanning systems are not yet capable of reading 2D barcodes. This dual-symbology ensures the shipping code can be read universally, preventing disruptions in the supply chain.

Human-Readable Interpretation (HRI): Printed clearly beneath each barcode, the HRI is essential for manual processing and error recovery. The full 18-digit shipping code number must be printed, after its GS1 Application Identifier in parentheses: sample (00)092558743668780032

Basic Delivery Information: The standard also mandates that key routing information be presented in human-readable form. This allows warehouse personnel, drivers, and receiving clerks to quickly identify and route the logistics unit if a barcode is damaged or a scanner fails.

Benefits of the S4T label

The S4T standard is designed for flexibility and future-proofing, offering key benefits such as:

Cross-carrier interoperability: Provides a universal language that all logistics partners can use, streamlining handoffs between different carriers.

Enhanced shipment and inventory visibility: Offers updated tracking data and access to rich digital information, giving all parties a clearer view of the shipment's status and contents.

Support for just-in-time delivery: The precision and data richness enable tighter scheduling and more accurate delivery windows, which are crucial for modern manufacturing and retail.

Offline resilience built in: The dual-symbology design ensures operations can continue even in environments with poor connectivity; the 2D barcode contains all essential data for basic identification and processing without requiring a live network connection.

Will the GS1 Digital Link QR code replace GS1-128?

The Scan4Transport standard requires that GS1-128 and GS1 Digital Link 2D barcodes appear together on logistics labels. This ensures compatibility since many warehouses and transport hubs still rely on 1D barcode scanners.

However, as logistics systems and equipment gradually become 2D barcode-capable, two barcodes may no longer be necessary.

In that future state, a single GS1 QR Code will be enough to carry both the SSCC and the richer digital data it enables. This shift highlights the broader role of QR codes in the supply chain, where the same symbol can support both identification and digital communication.

That transition will take time. Global supply chains are vast, with scanning infrastructure that can’t be swapped out overnight. Until then, both formats will coexist to guarantee smooth operations.

A constant identifier in an evolving supply chain

The SSCC still fulfills its original role of giving each logistics unit a unique identifier. Its value in traceability, warehouse automation, and shipment accuracy remains as strong as ever.

What has changed is the way that identifier is carried. In a GS1-128 barcode, it works as a reliable key that requires a database lookup. The same identifier becomes more dynamic in a GS1 Digital Link QR code, providing instant access to online shipment details.

The function stays the same, but the tools around it continue to improve. Logistics identification remains the foundation, whether scanned from a linear symbol or a 2D code. Once a simple label, it is also a digital gateway, ensuring its relevance as supply chains grow increasingly connected and data-driven.

FAQs

Where is the SSCC used?

It is mainly applied to transport units like pallets and cases. The code appears on logistics labels, most often encoded in a GS1-128 barcode or, more recently, in a GS1 Digital Link QR code.

Does the SSCC carry product details?

No. The Serial shipping container code itself is just an identifier. To get delivery information, status, or product details, the code must be looked up in the company’s database or accessed through linked digital systems.

What is the connection between Scan4Transport and the GS1 Digital Link?

Scan4Transport (S4T) is a global program that encourages using 2D barcodes on logistics and transport labels. These barcodes make it easier to share shipment details across different systems.

The GS1 Digital Link, on the other hand, is a standard way of putting product or shipment data into a web link (URI) so it can be read consistently.

In short, S4T focuses on where and why the barcodes are used in logistics, while GS1 Digital Link defines how the data inside those barcodes is structured.

DISCLAIMER: We acknowledge that GS1, as well as the materials, proprietary items, and all related patents, copyright, trademark, and other intellectual property (collectively, “intellectual property”) relating to its use, are the property of GS1 Global, and that our use of the same shall be in accordance with the conditions provided by GS1 Global.